In this article

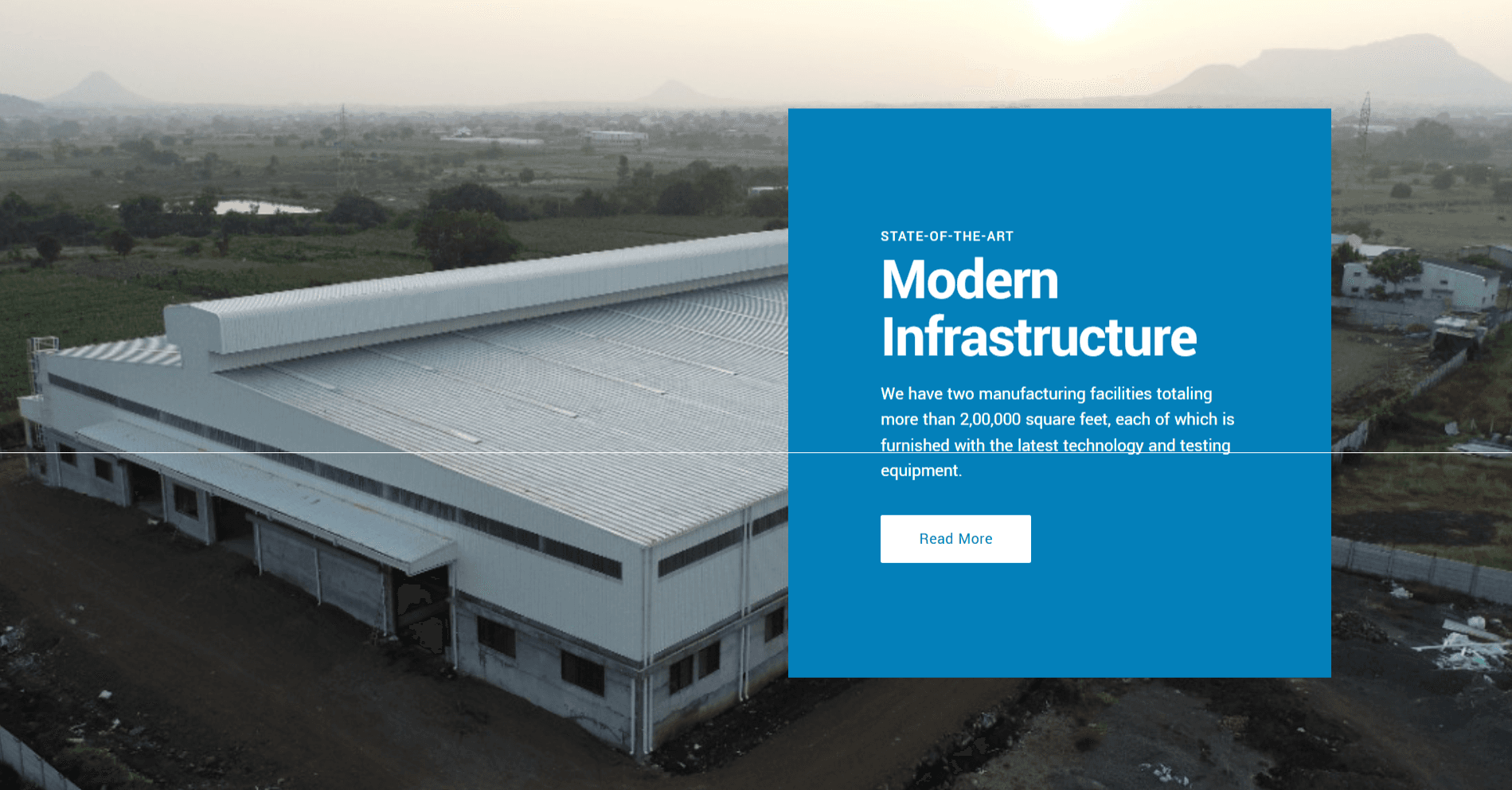

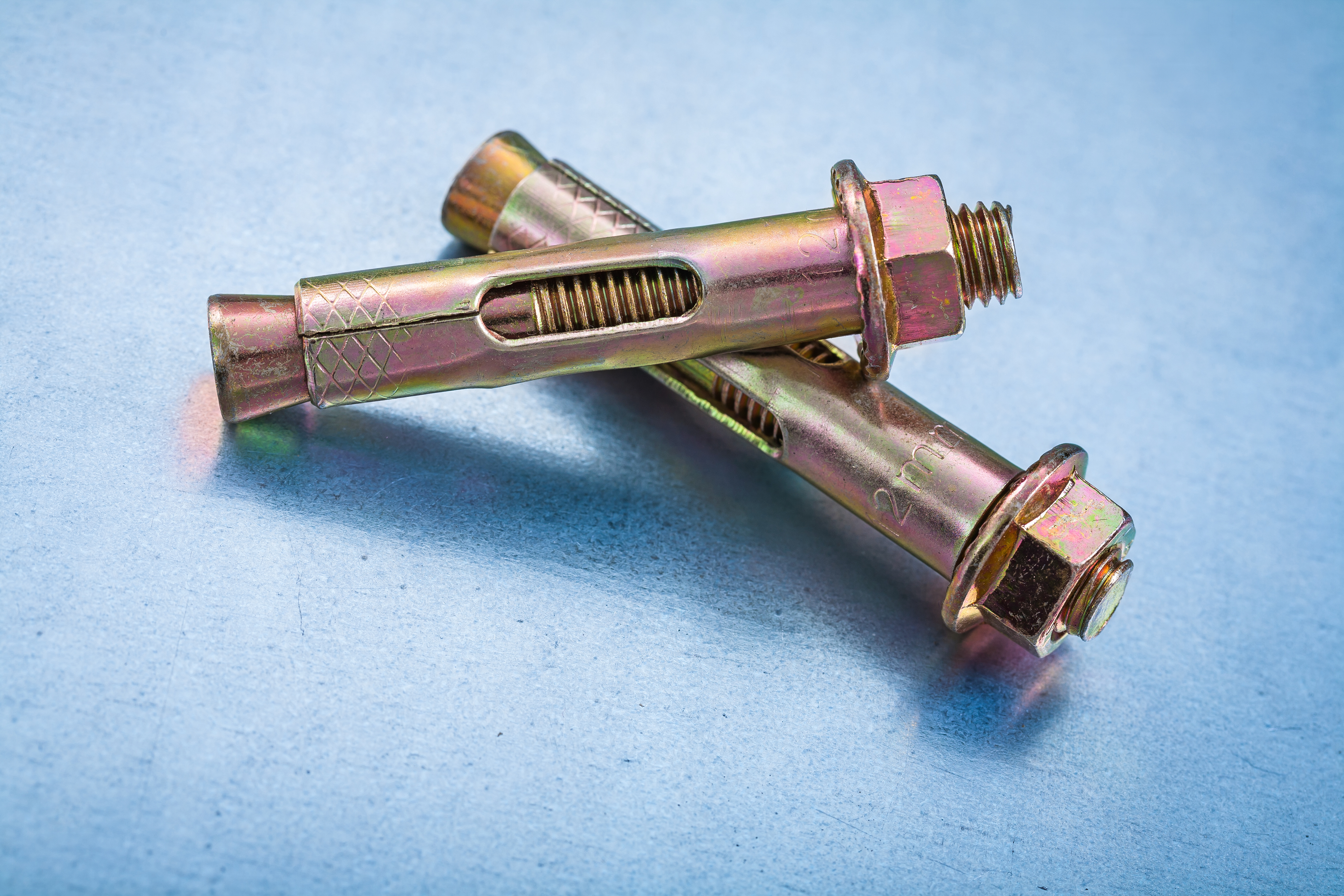

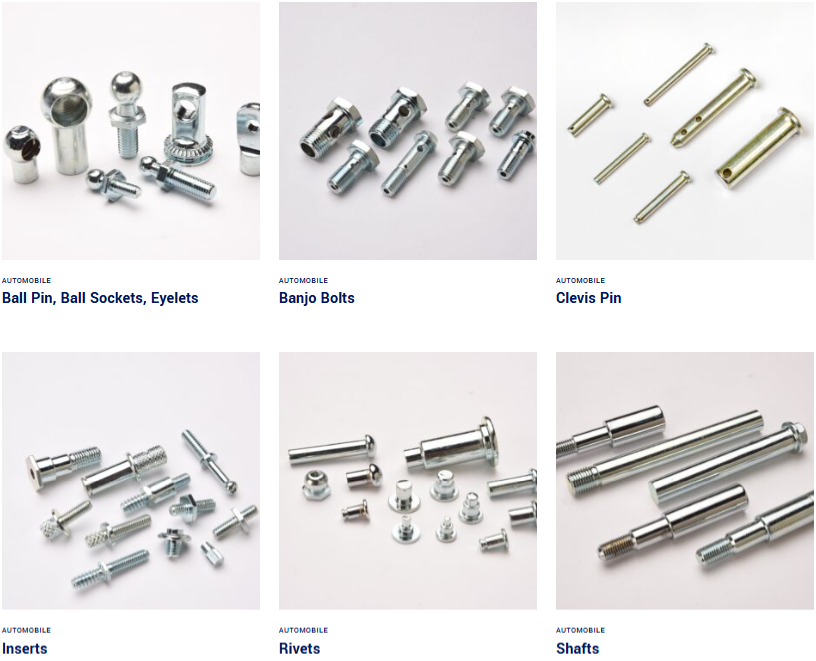

Developing a Custom Production Management and Automation System for Metaforge India

Metaforge India was managing complex production processes manually, which led to inefficiencies, errors, and delayed reporting. They required a custom software solution to:

Overcoming Operational and Technical Complexities in Forging Process Automation

The project involved several operational and technical challenges:

Developing a Custom Production Operations and Monitoring System for Metaforge India

Our team developed a custom production operations software tailored to Metaforge India’s workflows, focusing on automation, accuracy, and real-time monitoring.

Transforming Production Efficiency, Data Accuracy, and Scalability for Metaforge India

The automation software transformed Metaforge India’s operations, delivering significant improvements:

You reach out, we listen! Expect a quick confirmation that we’ve received your request.

Our experts dive into your needs and get back to you within 3 business days with practical insights.

Confidentiality matters—if needed, we can sign an NDA within 1-2 days to protect your project.

In just a few days, we’ll share an initial project estimate, recommendations, or next steps to get started.