Innova Rubbers – Production Operations Automation Software

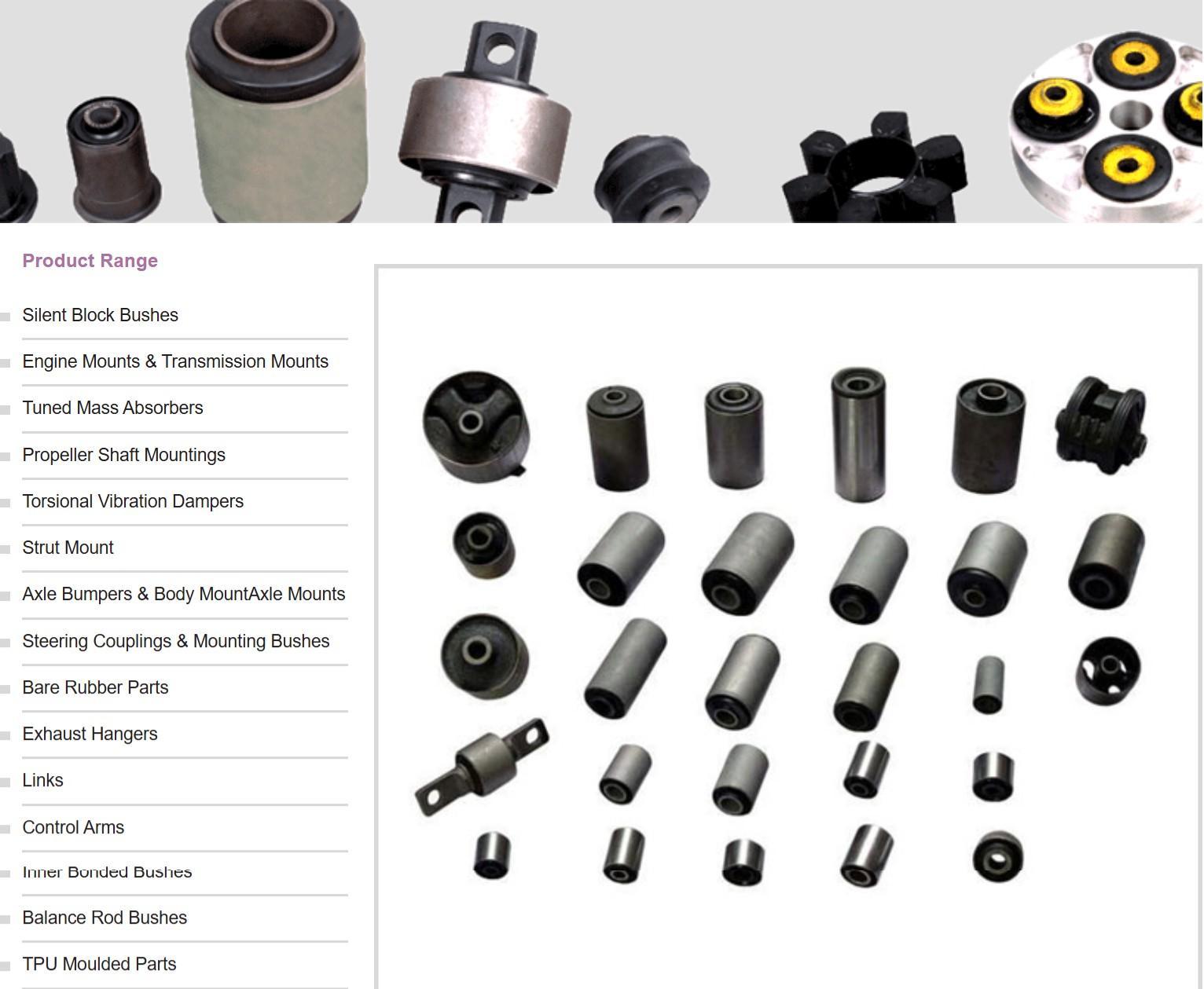

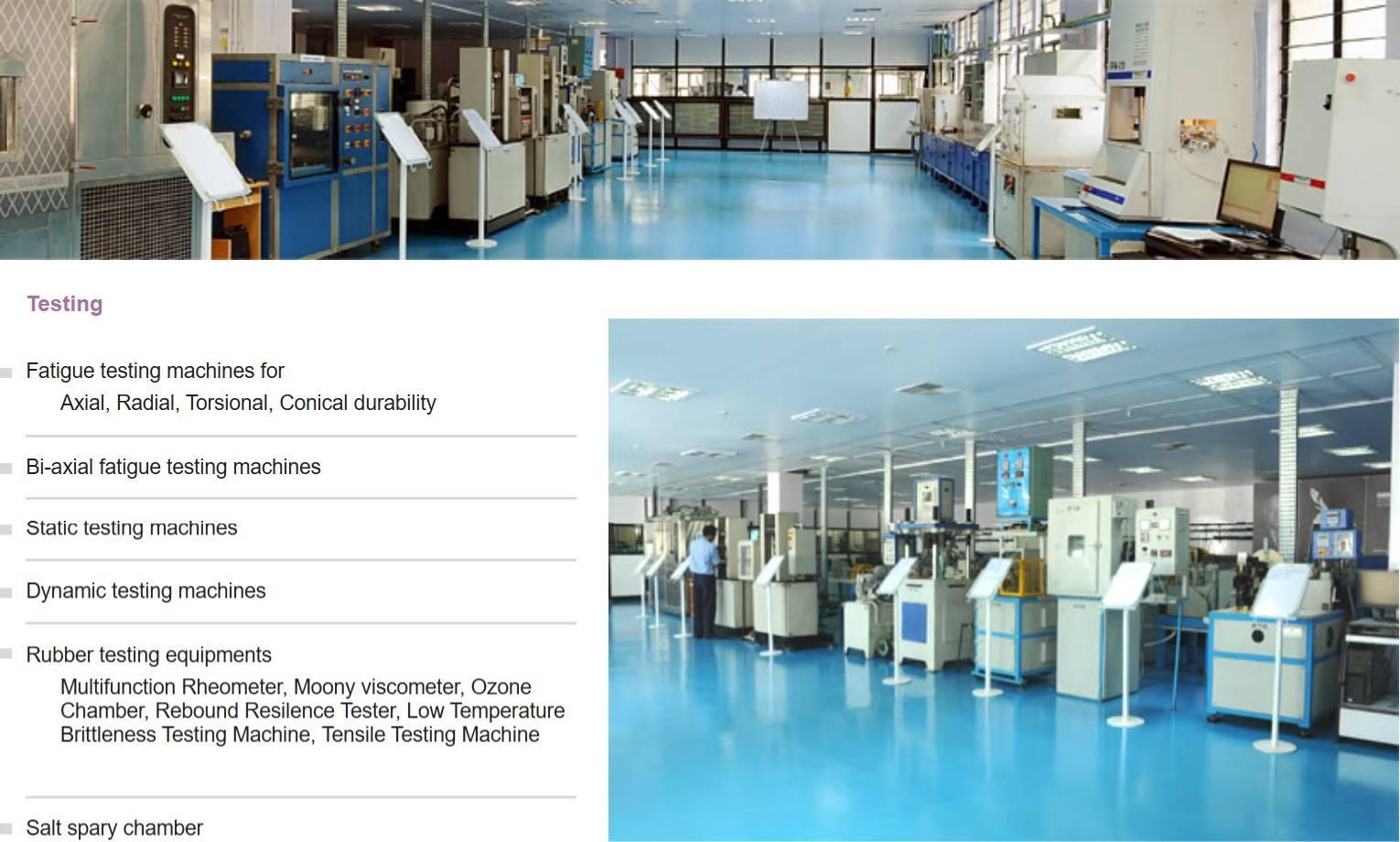

Innova Rubbers is a leading manufacturer of high-quality rubber components for the automotive and industrial sectors. The company is known for its precision engineering, consistent quality, and ability to deliver customized rubber solutions for OEMs and aftermarket clients worldwide.

Industry

Automotive & Industrial Rubber Manufacturing

Location

Nashik, Maharashtra

Challenge

Digitizing complex production operations and inventory workflows to enhance efficiency, accuracy, and scalability while integrating multiple departments into a unified management system.

Success Highlights

Innova Rubbers relied heavily on manual processes across production operations, inventory tracking, and order management. The client required a custom software solution to:

During the automation initiative, several operational and technical challenges needed to be addressed to ensure accuracy, scalability, and smooth integration across departments:

Our team developed a custom production operations software tailored to Innova Rubbers’ workflows, focusing on automation, accuracy, and scalability:

The implementation of the production automation software transformed Innova Rubbers’ operations by enabling data-driven decision-making, improving process visibility, and significantly reducing manual intervention. The system streamlined order processing, optimized resource utilization, and positioned the company for future scalability.

You reach out, we listen! Expect a quick confirmation that we’ve received your request.

Our experts dive into your needs and get back to you within 3 business days with practical insights.

Confidentiality matters—if needed, we can sign an NDA within 1-2 days to protect your project.

In just a few days, we’ll share an initial project estimate, recommendations, or next steps to get started.